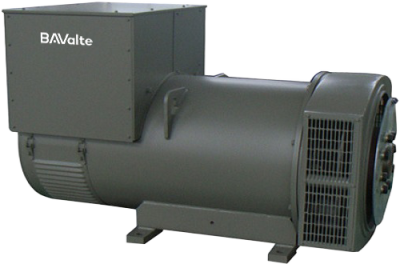

Alternator is a machine that converts mechanical energy into electrical energy. It typically consists of a rotor and stator, which work together to produce an electromagnetic field that generates electrical current. Alternators are commonly used in a wide range of applications, including power generation, backup power, and mobile power. They can be powered by a variety of sources, including gasoline, diesel, natural gas, propane, and renewable sources such as wind and solar.

Here are some key characteristics and advantages of alternators:

- Reliability: Alternators are a reliable source of electrical power, particularly in situations where there is no access to a power grid or during power outages. They can provide power quickly and reliably, helping to prevent downtime, equipment damage, and other costly disruptions.

- Flexibility: Alternators come in a wide range of sizes and capacities, making it possible to match the alternator to the specific power needs of the application. They can be used as a primary or backup power source, and can be powered by a variety of fuels.

- Portability: Many alternators are portable and can be easily transported to different locations as needed. This makes them well-suited for mobile power applications, as well as for use in remote locations where there is no access to a power grid.

- Efficiency: Alternators can be designed for high efficiency, meaning that they can convert a high percentage of the input energy into electrical energy. This can result in lower fuel consumption and lower emissions, depending on the type of fuel being used.

Alternators are an essential component of many power generation systems, providing reliable and flexible power in a wide range of applications. They can be powered by a variety of fuels, come in a wide range of sizes and capacities, and can be designed for high efficiency.

When choosing an alternator, there are several factors to consider to ensure that the alternator meets your specific power needs and requirements. Here are some key factors to consider:

- Power output: The most important factor to consider when choosing an alternator is the power output, which is measured in watts. You will need to determine how much power you require for your specific application in order to select an alternator with the appropriate power output.

- Run time: The run time of an alternator refers to how long it can operate on a single tank of fuel. You will need to consider the expected run time requirements for your specific application, and select an alternator with an appropriate fuel tank size and fuel efficiency.

- Noise level: Alternators can produce significant noise while in operation, which may be a concern in certain applications. You will need to consider the noise level of the alternator and select a model that meets your specific noise requirements.

- Portability: If you require a portable alternator, you will need to consider factors such as weight, size, and ease of transportation. Some alternators are designed for easy portability, while others are intended for stationary use.

- Cost: Finally, you will need to consider the cost of the alternator, including the initial purchase price, ongoing maintenance and fuel costs, and any installation or setup costs. You will need to balance the features and capabilities of the alternator against your budget to select a model that meets your needs at a reasonable cost.